Module 7 Extruding – Part 2

| Learning Outcomes |

When you have completed this module, you will be able to:

|

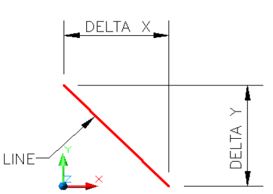

Point to Point Linear Dimensions

A point to point linear dimension is a dimension measuring the delta X or the delta Y distance between two points of an existing object or objects. The points, which are normally the endpoints of a line, could also be centre points of circles or arcs as you will see in future modules. If the points both lie on the same X or Y axis, the dimension can only inserted in one direction. If the points do not lie on the same axis, you have the choice of inserting either the delta X or the delta Y dimension. See Figure 7-1. The three steps used to insert a point to point linear dimension are shown below.

| Inventor Command: 2D SKETCH |

| The 2D SKETCH command is used to create a 2D sketch on a sketching plane or onto an existing 3D solid model.

Shortcut: S |

|

WORK ALONG: Constructing a Solid Model Using Multiple Sketches

Step 1

Check the default project and if necessary, set it to Inventor Course.

Step 2

Enter the NEW command to start a new part file using the template: Metric-Modules Part (mm).ipt.

Step 3

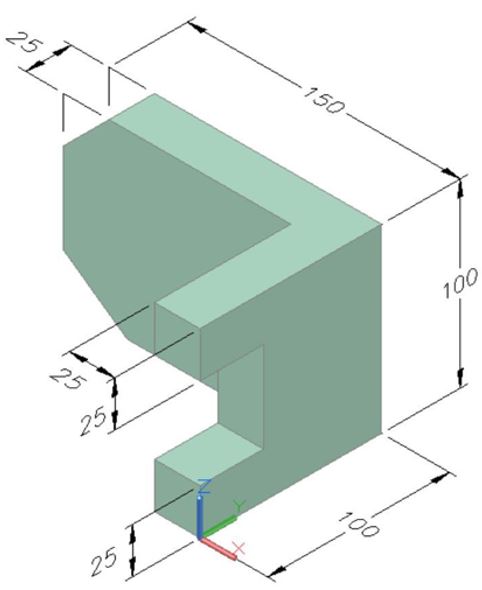

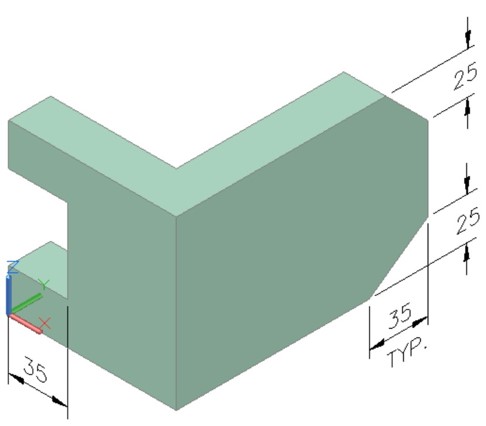

Save the file with the name: Inventor Workalong 07-1. (Figure Step 3A and 3B)

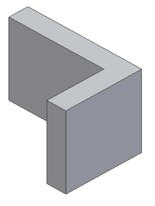

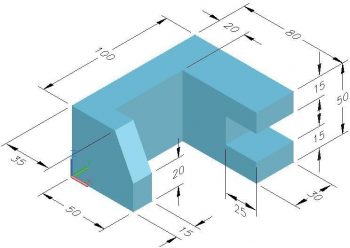

| AUTHOR’S COMMENTS: Two views of the model that you will be constructing in this workalong are shown below. Note the location of X0Y0Z0. |

Step 4

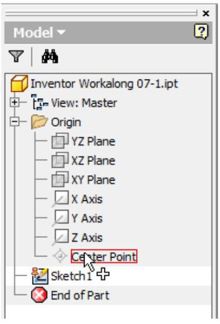

Edit Sketch 1 and enter the PROJECT GEOMETRY command and project the Center Point onto the sketching plane. Press Esc to exit the command. (Figure Step 4)

Step 5

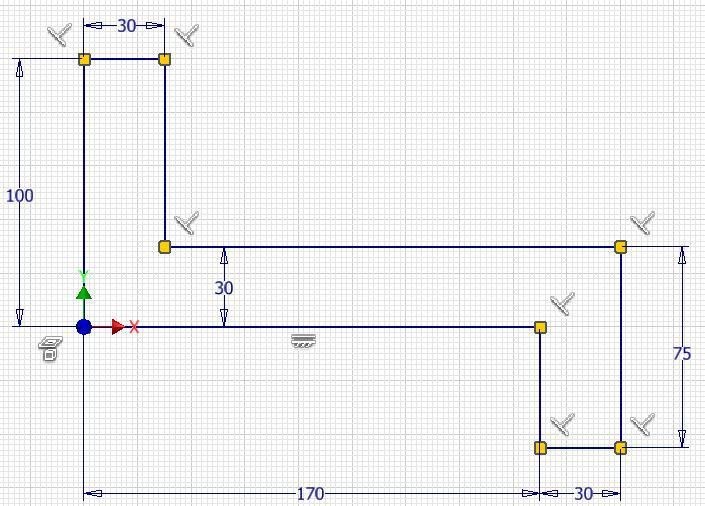

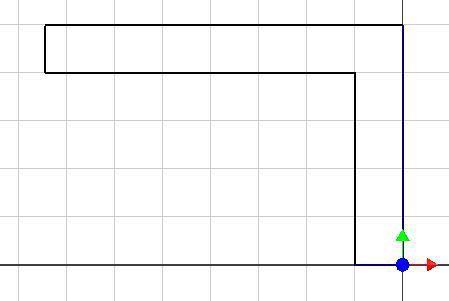

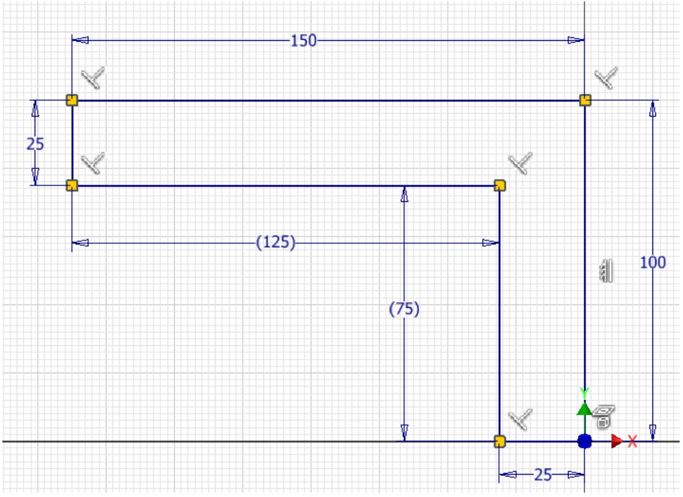

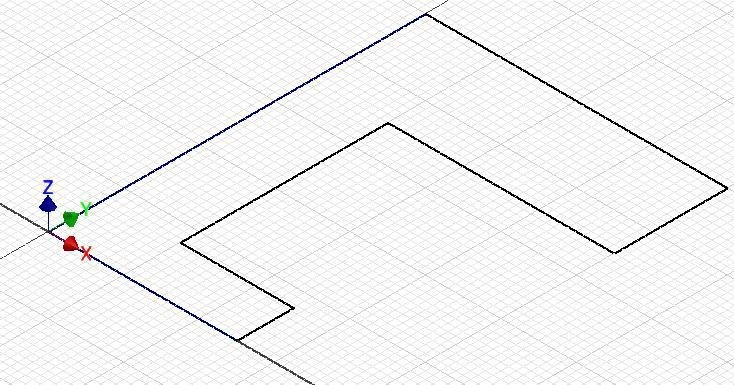

Draw the Top view of the model starting at X0Y0Z0. This is the Base sketch. (Figure Step 5)

| AUTHOR’S COMMENTS: Since the most contoured shape of the model is the Top view, this is the view the should be drawn first. |

Step 6

Add 4 driving dimensions to fully constrain the sketch. Add 2 driven dimensions.

Step 7

Press F8 to display the constraints. (Figure Step 7)

Step 8

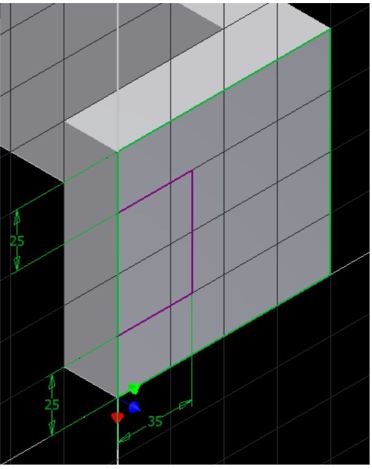

The sketch should now be fully constrained and all the lines display purple on a black background. (Figure Step 8)

Step 9

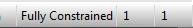

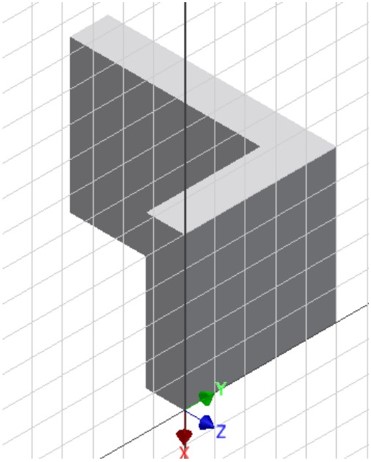

Press F6 to change the view to the Home view. Click the FINISH SKETCH command to return to Model mode. (Figure Step 9)

Step 10

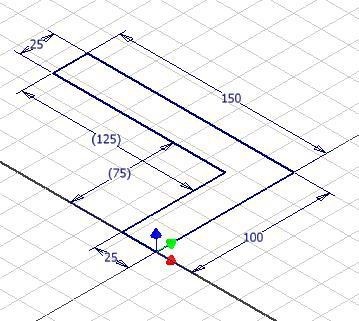

Enter E to execute the EXTRUDE command and extrude the model 100 mm in the positive Z direction. (Figure Step 10)

Step 11

The solid model should appear as shown in the figure. (Figure Step 11)

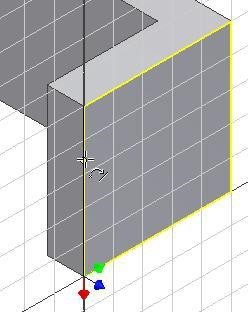

Step 12

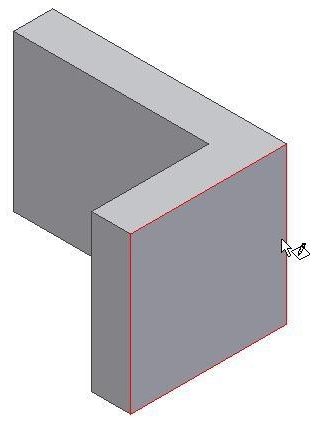

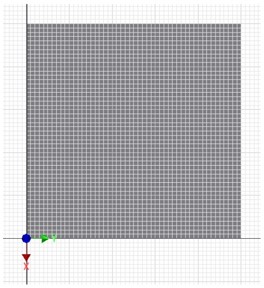

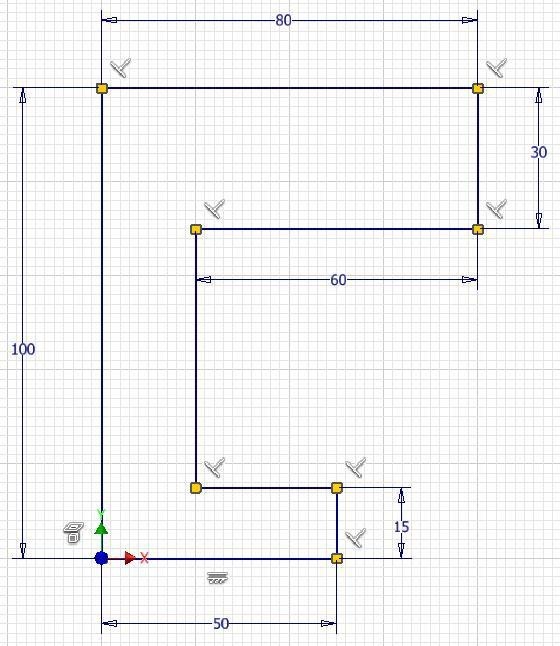

Click the 2D SKETCH icon and when prompted, select the right side plane as shown in the figure. Exit the command and the grid will display on the plane in Sketch mode. Press F6 to change to the Home view. (Figure Step 12A, 12B, and 12C)

Step 13

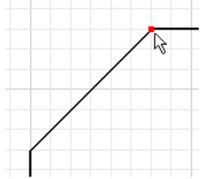

Enter L for the LINE command and start the first endpoint of the line by snapping onto the plane edge line. (Figure Step 13)

| AUTHOR’S COMMENTS: The exact location on the line is not important. Guess at a location about 25 millimeters from the top. It MUST, however, be snapped onto the edge. |

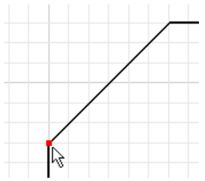

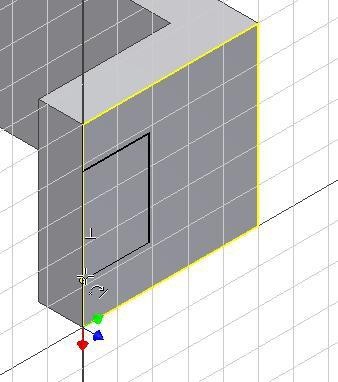

Step 14

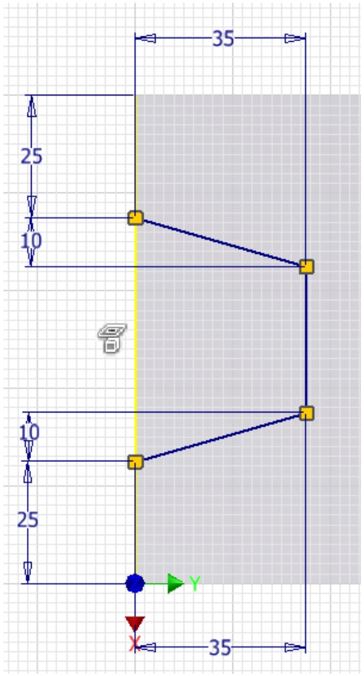

Draw three lines, applying perpendicular geometrical constraints and snapping back onto the edge. Guess at the length of the lines making them approximately the correct length. (Figure Step 14)

Step 15

Press F8 to display the constraint icons. (Figure Step 15)

| AUTHOR’S COMMENTS:Your constraints may not match the figure exactly. |

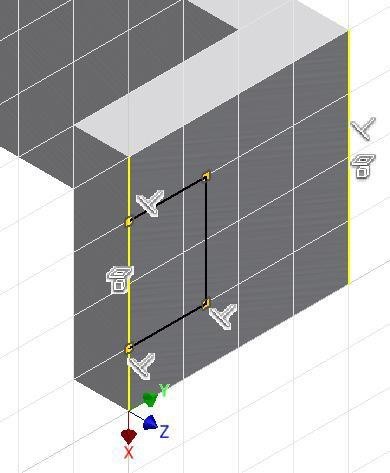

Step 16

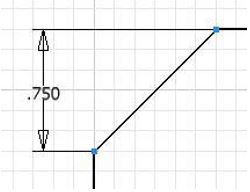

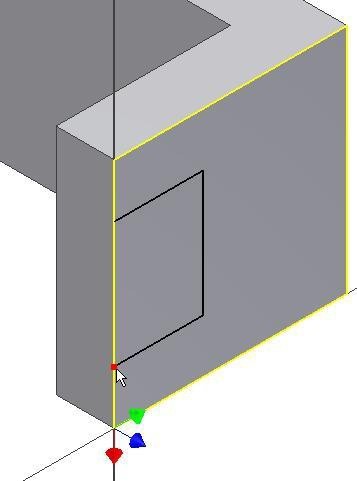

Enter D for the GENERAL DIMENSION command. Move the cursor to bottom corner of the model. When a small point highlights, click the mouse. (Figure Step 16)

Step 17

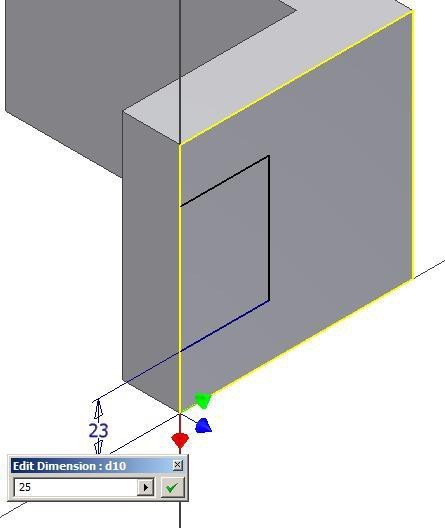

For the second point of the dimension, click the end of the line as shown in the figure. Locate and set the dimension to 25. (Figure Step 17A and 17B)

Step 18

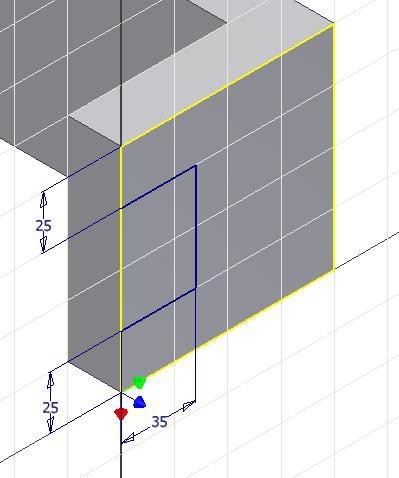

Add two additional dimensions to fully constrain it. (Figure Step 18A, 18B, and 18C)

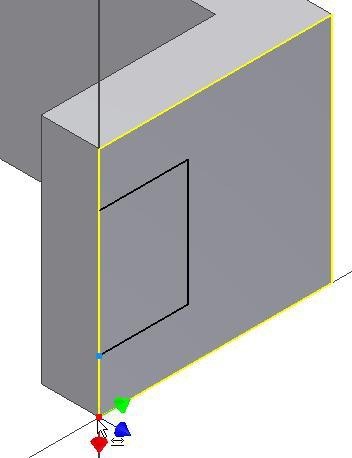

Step 19

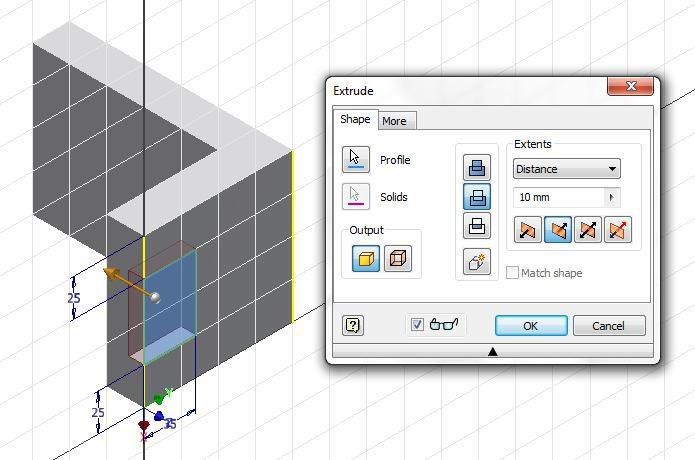

Enter E for the EXTRUDE command. (Figure Step 19)

Step 20

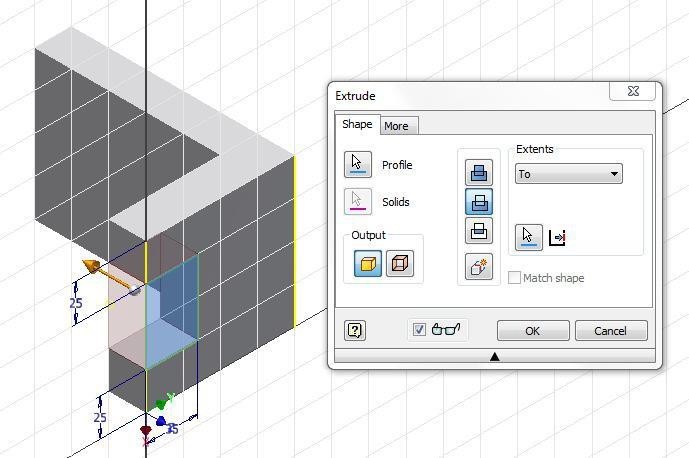

Set the Extents to To, the type to Cut and select the back face to locate where to extrude to. (Figure Step 20)

Step 21

Your model should appear as shown in the figure. (Figure Step 21)

Step 22

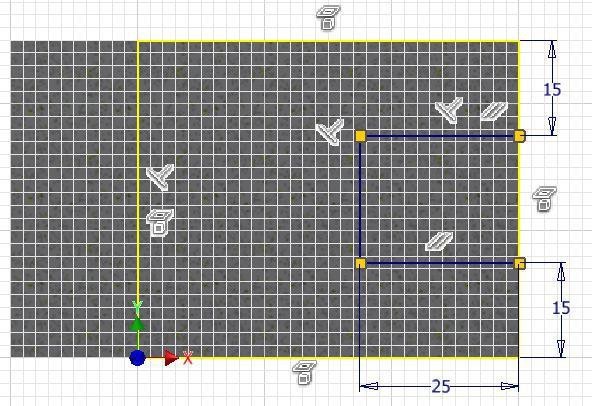

Click the 2D Sketch icon and select the top plane to start a new sketch. Orbit the model to match the figure. (Figure Step 22)

Step 23

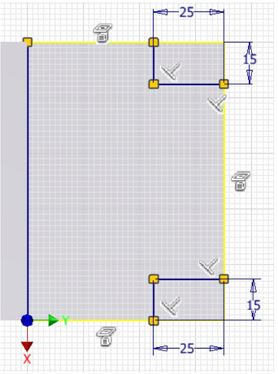

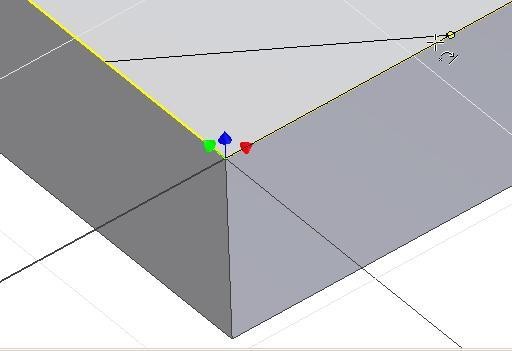

On the sketch, draw a line across the corner. Make sure that you snap both ends of the line to the edges. Guess at the distance from the corner. (Figure Step 23)

Step 24

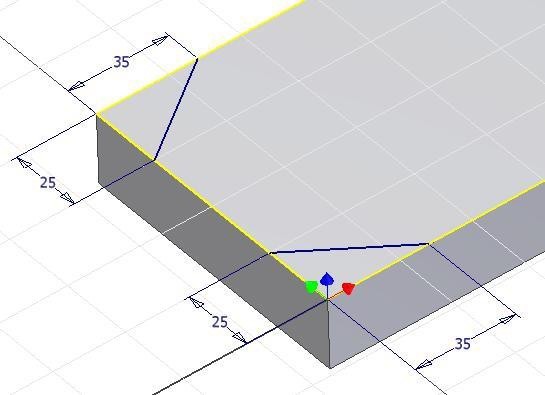

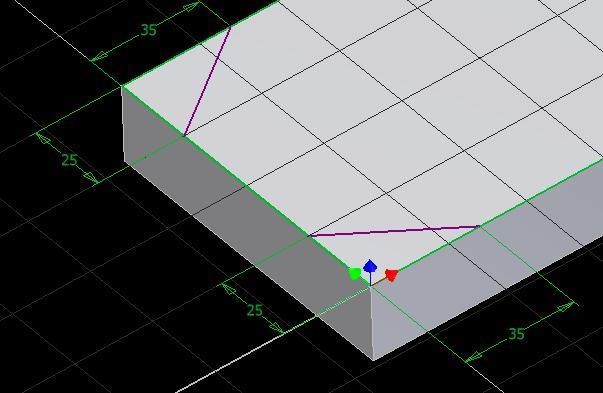

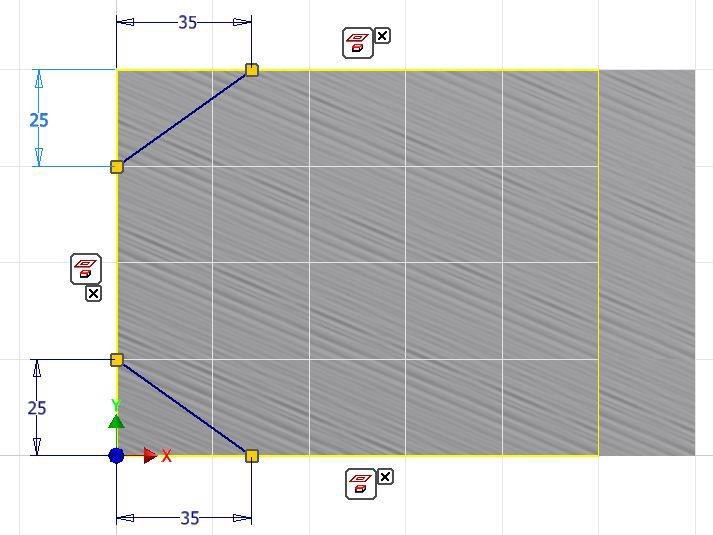

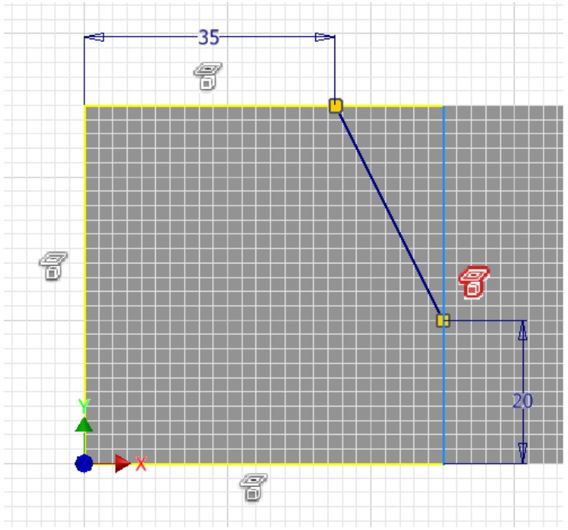

Draw a line on the opposite side and dimension both lines using four point to point dimensions. (Figure Step 24)

Step 25

Your sketch should be fully constrained as shown in the figure. (Figure Step 25)

Step 26

Press F8 to display the constraint icons. (Figure Step 26)

| AUTHOR’S COMMENTS:Your constraints may not match the figure exactly. |

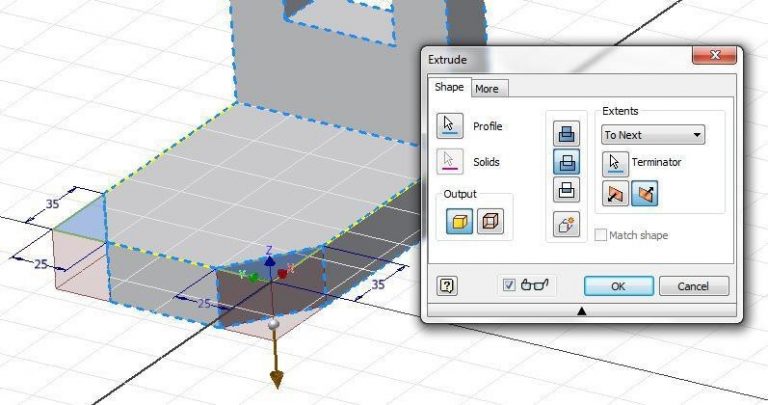

Step 27

Extrude the sketch using the To Next extents. Select the two profiles to extrude and ensure that you enable the Cut icon. (Figure Step 27)

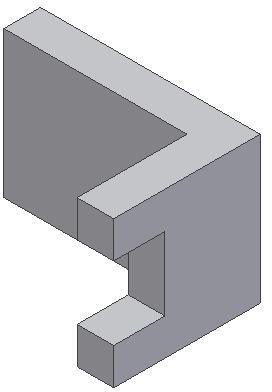

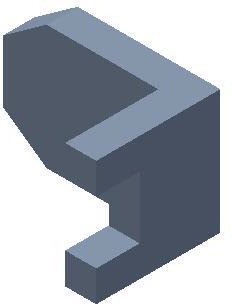

Step 28

Change to the Home view by pressing F6. Change the colour of the completed model to color: Light Steel Blue. (Figure Step 28)

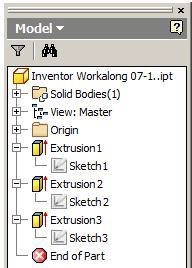

Step 29

Expand the Browser bar. You can see that the model hierarchy shows the three sketches and an extrusion of each one. (Figure Step 29)

Step 30

Save and close the file.

Key Principles

| Key Principles in Module 7 |

|

Lab Exercise 7-1

Time allowed: 45 minutes.

| Part Name | Project | Units | Template | Color | Material |

| Inventor Lab 07-1 | Inventor Course | Millimeters | Metric-Modules Part (mm).ipt | Steel | N/A |

Step 1

Project the Center Point onto the sketching plane.

Step 2

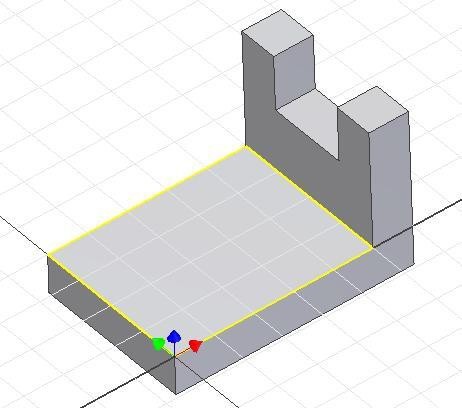

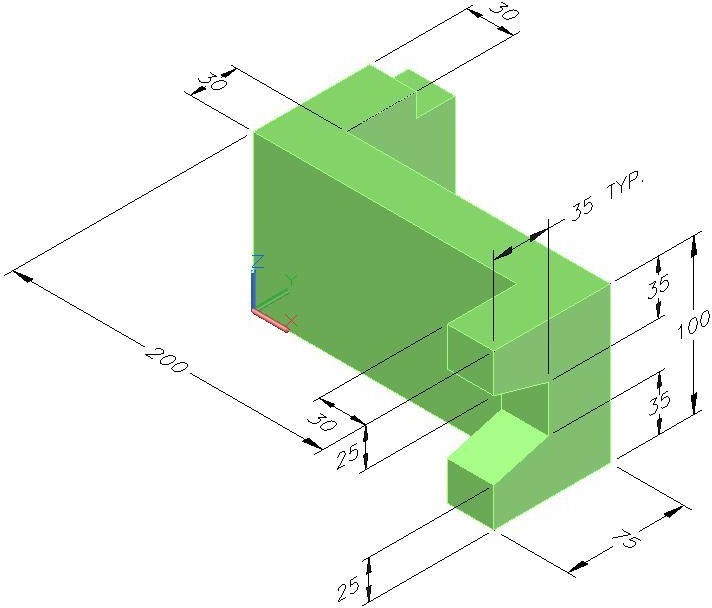

Note the location of X0Y0Z0. Draw the necessary sketches and extrude them to produced the solid model. Apply all of the necessary geometrical and dimensional constraints to fully constrain all sketches. (Figure Step 2A and 2B)

Step 3

Apply the colour shown above. (Figure Step 3)

| AUTHOR’S GEOMETRIC CONSTRAINS: The following three figures shows the base and additional sketch’s construction method plus geometric and dimensional constraints suggested by the author to help you learn how to construct and constrain sketches. It is only the suggested method and if you can complete a fully constrained sketches using different construction methods and constraints, that is what is important. You may want to compare your construction method and constraints used with the authors. |

|

|

|

Lab Exercise 7-2

Time allowed: 45 minutes.

| Part Name | Project | Units | Template | Color | Material |

| Inventor Lab 07-2 | Inventor Course | Millimeters | Metric-Modules Part (mm).ipt | Chrome – Polished | N/A |

Step 1

Project the Center Point onto the base sketching plane.

Step 2

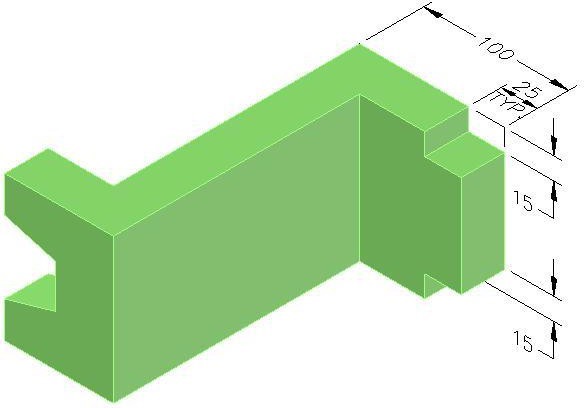

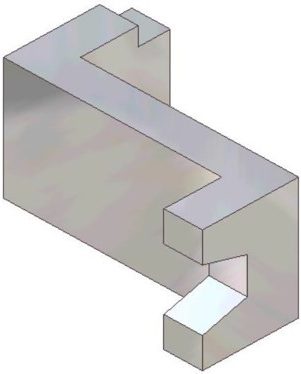

Note the location of X0Y0Z0. Draw the necessary sketches and extrude them to produced the solid model. Apply all of the necessary geometrical and dimensional constraints to fully constrain all sketches. (Figure Step 2A, 2B, and 2C)

Step 3

Apply the colour shown above. (Figure Step 3)

Step 4

Save the file with the name: Inventor Lab 07-2 as shown above.

| AUTHOR’S GEOMETRIC CONSTRAINTS: The following three figures shows the base and additional sketch’s construction method plus geometric and dimensional constraints suggested by the author to help you learn how to construct and constrain sketches. It is only the suggested method and if you can complete a fully constrained sketches using different construction methods and constraints, that is what is important. You may want to compare your construction method and constraints used with the authors. |